OE No.:

96199017 96127209 CSC0429Bore Size:

22.22mmMaterial:

Cast ironApplication:

daewoo busBrand:

KOMPOrder(MOQ):

50-100 pcsShipping Port:

Shanghai, Ningbo, Tianjin, GuangzhouLead Time:

1-30 daysProduct Detail

DAEWOO Clutch Master Cylinder OE Replacement Part

|

|

About KOMP Our Product Range:

Global Reach: |

Experience unmatched braking performance with our premium 96199017 clutch master cylinder for daewoo! Can withstand -40℃-90℃. Durable, reliable, and built for heavy-duty vehicles, it ensures safety and precision every time.

96199017 96127209 CSC0429

DAEWOO bus clutch master cylinder

‧Parts Brand

DAEWOO

‧Parts Model

BUS

‧Parts OEM Number

‧Parts

Clutch master cylinder

‧Parts Description

Cast iron clutch master cylinder for daewoo bus

‧Vihecles Fitted

|

Products advantage

|

|

|

ZL111 Aluminium Material

For aluminum products, use ZL111 Aluminum material, hardness higher than 110HB, and we can do Sand Blasting, Original Oxidation, Hard Oxidation, and Dacromet according to customer needs |

|

|

Electrophoresis Process For iron products, we will use electrophoresis technology to achieve the effect of no rustand smooth surface. |

|

|

Piston Hard Anodized The piston are all hard anodized, high precision, good wear resistance and not easy to rust. |

|

|

EPDM Material The rubber ring uses EPDM as the raw material labeled EP-35, all are imported from Japan to bring better sealing performance and oil return characteristics. And recommended to use DOT 4 or higher standard brake fluid. |

|

|

With Anti-dust Plug Prevent oil and dust from entering, avoid collision with sharp objects, and ensure the integrity of the oil outlet thread. |

|

|

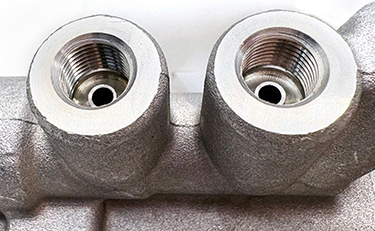

High Precision The thread is finely crafted, with high precision and no defects. The surface is treated very smoothly. |

After Service

Warranty

1 year / 30,000 km

Support

Technology support for any after-service

OEM service

Customized Laser Marking and Color Box

Packaging & Delivery

1. Plastic bag+ Neutral box+ Carton

2. Plastic bag + Color box KOMP + Carton

3. Pallet

4. Customized by request.

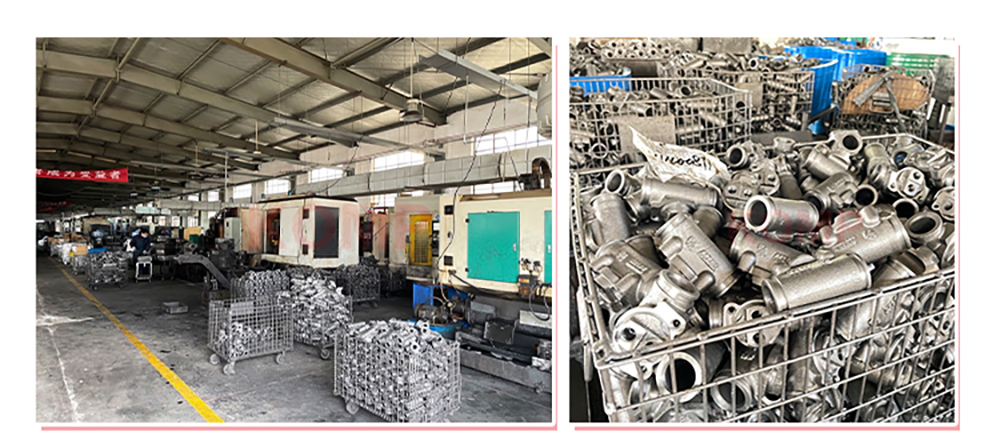

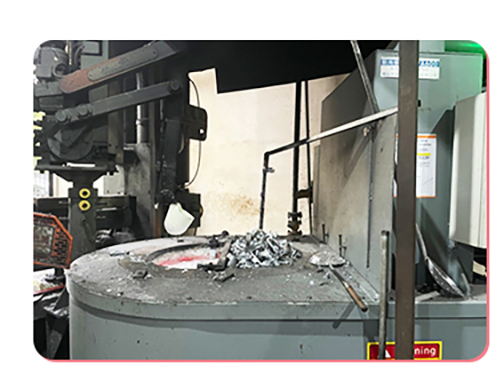

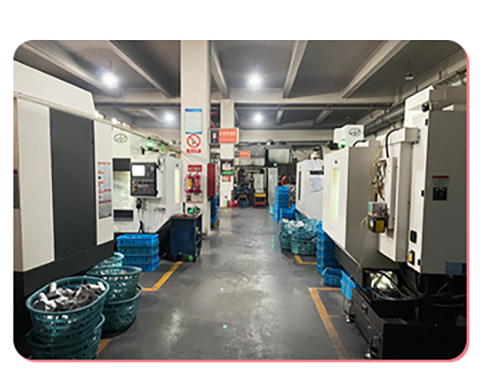

Factory Tour

Our Product Progress

Step1: Casting

Step2: CNC Workshop

Step3: Honing

Step4: Ultra-Sonic Cleaning

Step5: Assembly

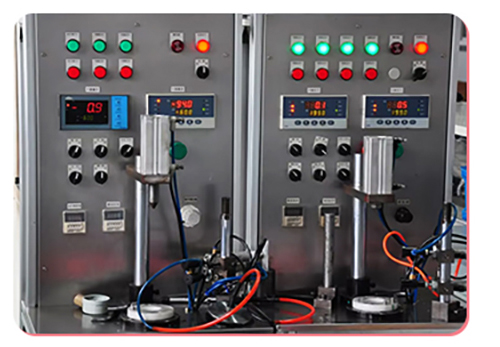

Step6: On-Line Test

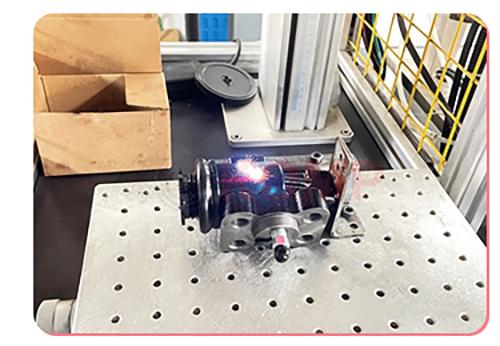

Step7: Laser Marking

Step8: Packing Workshop

Certification