How does the clutch master cylinder work?

May 30, 2025

How does the clutch master cylinder work?

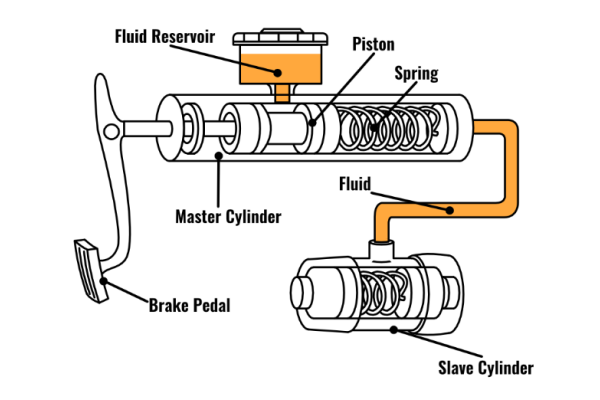

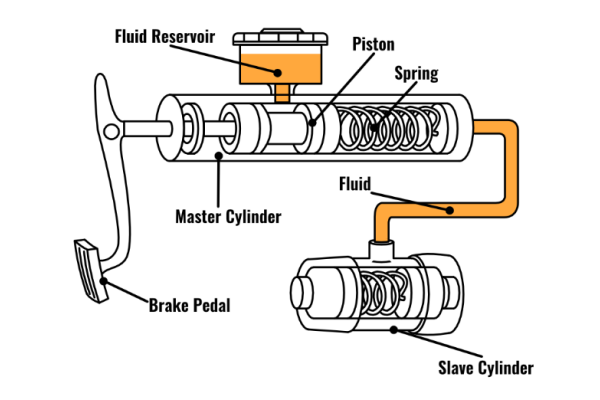

Working principle of hydraulic transmission system

As the power source of hydraulic clutch systems, the clutch master cylinder plays a vital role in ensuring smooth gear transitions.

The clutch master cylinder operates through three distinct working stages:

1. Pressure building stage

When the pedal is pressed, the push rod activates the main piston, compressing the hydraulic oil. At this point, the compensation hole closes, and system pressure increases linearly (0.7–1.2 MPa pressure is generated per millimeter of stroke). Many factory clutch master cylinder configurations now adopt a progressive pressure curve, enabling smoother initial pressure buildup to enhance driving comfort.

2. Pressure transmission stage

The pressurized hydraulic oil travels to the clutch slave cylinder via reinforced nylon pipelines (typically 4.5–6mm in diameter). Transmission efficiency depends on:

Oil viscosity (DOT4 standard: ≤1800 mm²/s at -40°C)

Pipeline routing (bending radius > 5× pipe diameter)

System air removal (air pockets may cause up to 30% pressure loss)

Leading supplier clutch master cylinder manufacturers often test these parameters rigorously to ensure consistent quality across various vehicle platforms.

3. Pressure release stage

When the pedal is released, the return spring resets the piston, and the compensation hole reopens to stabilize the pressure. High-performance models might include a rapid oil return valve, reducing reset time to under 0.2 seconds.

Typical failure modes

Progressive failure – Worn seals cause slow pressure buildup (symptom: increased pedal travel)

Sudden failure – Cracks in the master cylinder lead to hydraulic leakage (ensure surface hardness ≥ HB80)

Temperature sensitivity – High temperatures may vaporize the fluid, softening pedal response

For models like the Ford Fiesta clutch master cylinder, it’s essential to select high-quality components from trusted suppliers to avoid premature failure.

Maintenance practice guide

Preventive maintenance:

Replace hydraulic oil every 2 years or 40,000 km

Check pedal free travel regularly (target: 10–15mm)

Use specialized tools (e.g., BET-300) for system bleeding

Modification precautions

Competition modifications require upgrading the sub-pump’s pressure tolerance

Quick-displacement kits must align with the clutch master cylinder’s oil delivery rate

Do not mix hydraulic oils of different specifications

Fault diagnosis process

A[Abnormal pedal] --> B{Pressure test}

B -->|Insufficient pressure| C[Check sealing system]

B -->|Normal pressure| D[Check mechanical connection]

C --> E[Replace maintenance kit]

D --> F[Adjust connecting rod mechanism]

2. Pressure transmission stage

The pressurized hydraulic oil travels to the clutch slave cylinder via reinforced nylon pipelines (typically 4.5–6mm in diameter). Transmission efficiency depends on:

Oil viscosity (DOT4 standard: ≤1800 mm²/s at -40°C)

Pipeline routing (bending radius > 5× pipe diameter)

System air removal (air pockets may cause up to 30% pressure loss)

Leading supplier clutch master cylinder manufacturers often test these parameters rigorously to ensure consistent quality across various vehicle platforms.

3. Pressure release stage

When the pedal is released, the return spring resets the piston, and the compensation hole reopens to stabilize the pressure. High-performance models might include a rapid oil return valve, reducing reset time to under 0.2 seconds.

Typical failure modes

Progressive failure – Worn seals cause slow pressure buildup (symptom: increased pedal travel)

Sudden failure – Cracks in the master cylinder lead to hydraulic leakage (ensure surface hardness ≥ HB80)

Temperature sensitivity – High temperatures may vaporize the fluid, softening pedal response

For models like the Ford Fiesta clutch master cylinder, it’s essential to select high-quality components from trusted suppliers to avoid premature failure.

Maintenance practice guide

Preventive maintenance:

Replace hydraulic oil every 2 years or 40,000 km

Check pedal free travel regularly (target: 10–15mm)

Use specialized tools (e.g., BET-300) for system bleeding

Modification precautions

Competition modifications require upgrading the sub-pump’s pressure tolerance

Quick-displacement kits must align with the clutch master cylinder’s oil delivery rate

Do not mix hydraulic oils of different specifications

Fault diagnosis process

A[Abnormal pedal] --> B{Pressure test}

B -->|Insufficient pressure| C[Check sealing system]

B -->|Normal pressure| D[Check mechanical connection]

C --> E[Replace maintenance kit]

D --> F[Adjust connecting rod mechanism]