How to Replace a Brake Wheel Cylinder?

Dec 12, 2025

How to Replace a Brake Wheel Cylinder?

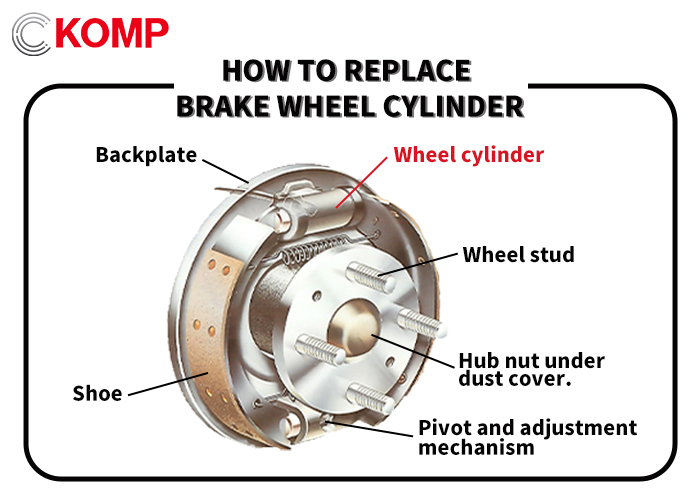

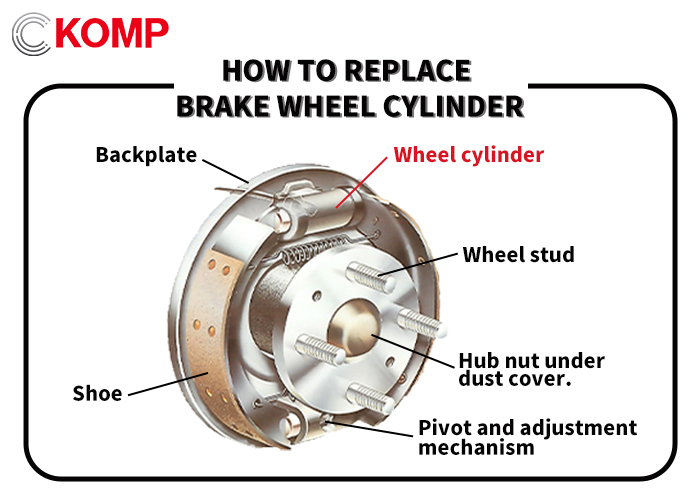

A brake wheel cylinder plays an essential role in drum-brake systems. When hydraulic pressure builds inside the brake lines, the small pistons within the cylinder push outward, forcing the brake shoes against the rotating drum. When a wheel cylinder leaks or becomes stuck due to corrosion or wear, the braking system loses efficiency and may even become unsafe. Replacing the faulty unit with a new brake wheel cylinder ensures the braking system can return to proper performance. Many drivers prefer choosing an OEM brake wheel cylinder for guaranteed fit and durability.

Preparation Before Starting

Since opening the hydraulic system can cause brake fluid to escape, take a few precautions to minimize mess and reduce the amount of air introduced into the system. Remove the reservoir cap from the master cylinder, stretch a thin piece of plastic over the opening, and reinstall the cap. This creates a mild internal seal that slows fluid flow while you work. If the vehicle uses flexible brake hoses, use a proper brake-hose clamp to lightly pinch the hose, further limiting fluid loss. For added confidence, some technicians consult guidance from a trusted brake wheel cylinder company before beginning the process.

1. Remove the Brake Drum and Shoes

Begin the repair by taking off the brake drum. With the drum removed, the brake shoes, springs, adjuster, and wheel cylinder will be exposed. Take note of their arrangement or take a picture for easy reassembly later. Remove the shoes and hardware so you can access the wheel cylinder without obstruction.

2. Unfasten the Wheel Cylinder

Locate the brake pipe where it connects to the back of the wheel cylinder. Use the correct flare-nut wrench to loosen the union. If the fitting is stubborn, penetrating oil can help break the corrosion. Next, detach the wheel cylinder from the backing plate. Depending on the vehicle, it may be secured with bolts, small screws, spring clips, or an E-clip.

3. Remove Retaining Clips or Bolts

Different vehicles use different mounting methods:

(1) Some cylinders are held with one or two bolts—simply remove them.

(2) Others use a spring-steel E-clip that snaps into a groove; carefully pry it off and discard it.

(3) Sliding-type cylinders may use two interlocked clips that must be separated before the unit can be removed.

After removing the old cylinder, clean the area on the backing plate to ensure the new part seats properly.

4. Disconnect the Brake Line

Hold the brake-pipe nut steady while gently twisting the old cylinder to free it. Avoid allowing the metal pipe to bend or twist. Once disconnected, cover the open pipe end to keep dirt out.

5. Install the New Cylinder

Fit the replacement unit in the same position as the old one. Install any new clips, gaskets, or bolts included with the part. Thread the brake pipe in by hand first to avoid cross-threading, then tighten securely.

6. Reassemble and Bleed the Brakes

Reinstall the shoes, springs, and drum. Once everything is in place, bleed the brake system to remove any air. Continue bleeding until clean, bubble-free fluid flows. Confirm that the brake pedal feels firm before driving.

Safety Reminders

1. Always support the vehicle securely with axle stands or ramps before working underneath.

2. Brake fluid can damage paint and irritate eyes—protective eyewear and careful handling are essential.

3. Replace old or contaminated brake fluid during the service for improved reliability.

4. After bleeding the brakes, test the pedal—if it feels soft, bleed the system again before driving.

Preparation Before Starting

Since opening the hydraulic system can cause brake fluid to escape, take a few precautions to minimize mess and reduce the amount of air introduced into the system. Remove the reservoir cap from the master cylinder, stretch a thin piece of plastic over the opening, and reinstall the cap. This creates a mild internal seal that slows fluid flow while you work. If the vehicle uses flexible brake hoses, use a proper brake-hose clamp to lightly pinch the hose, further limiting fluid loss. For added confidence, some technicians consult guidance from a trusted brake wheel cylinder company before beginning the process.

1. Remove the Brake Drum and Shoes

Begin the repair by taking off the brake drum. With the drum removed, the brake shoes, springs, adjuster, and wheel cylinder will be exposed. Take note of their arrangement or take a picture for easy reassembly later. Remove the shoes and hardware so you can access the wheel cylinder without obstruction.

2. Unfasten the Wheel Cylinder

Locate the brake pipe where it connects to the back of the wheel cylinder. Use the correct flare-nut wrench to loosen the union. If the fitting is stubborn, penetrating oil can help break the corrosion. Next, detach the wheel cylinder from the backing plate. Depending on the vehicle, it may be secured with bolts, small screws, spring clips, or an E-clip.

3. Remove Retaining Clips or Bolts

Different vehicles use different mounting methods:

(1) Some cylinders are held with one or two bolts—simply remove them.

(2) Others use a spring-steel E-clip that snaps into a groove; carefully pry it off and discard it.

(3) Sliding-type cylinders may use two interlocked clips that must be separated before the unit can be removed.

After removing the old cylinder, clean the area on the backing plate to ensure the new part seats properly.

4. Disconnect the Brake Line

Hold the brake-pipe nut steady while gently twisting the old cylinder to free it. Avoid allowing the metal pipe to bend or twist. Once disconnected, cover the open pipe end to keep dirt out.

5. Install the New Cylinder

Fit the replacement unit in the same position as the old one. Install any new clips, gaskets, or bolts included with the part. Thread the brake pipe in by hand first to avoid cross-threading, then tighten securely.

6. Reassemble and Bleed the Brakes

Reinstall the shoes, springs, and drum. Once everything is in place, bleed the brake system to remove any air. Continue bleeding until clean, bubble-free fluid flows. Confirm that the brake pedal feels firm before driving.

Safety Reminders

1. Always support the vehicle securely with axle stands or ramps before working underneath.

2. Brake fluid can damage paint and irritate eyes—protective eyewear and careful handling are essential.

3. Replace old or contaminated brake fluid during the service for improved reliability.

4. After bleeding the brakes, test the pedal—if it feels soft, bleed the system again before driving.