In the automotive world, the brake system plays a crucial role in ensuring safety on the roads. At the heart of this system lies the brake master cylinder, a key component responsible for converting the driver's input into hydraulic pressure that activates the braking mechanism. This blog post aims to explore the working principle and classification of the brake master cylinder, shedding light on its vital role in vehicle braking systems.

Working Principle:

The brake master cylinder functions based on the principle of hydraulic

pressure amplification. When the driver applies force to the brake pedal, a

piston inside the master cylinder is pushed forward, compressing the brake

fluid within the cylinder. This compression creates hydraulic pressure, which

is then transmitted to the brake calipers or wheel cylinders, resulting in the

application of the brakes.

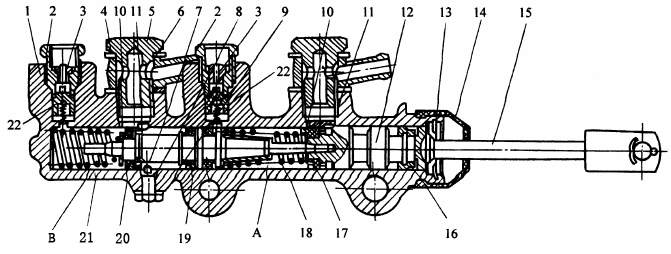

Internal Components:

The brake master cylinder comprises several essential components, including a

reservoir, piston, primary and secondary chambers, and seals. The reservoir

stores the brake fluid, allowing it to be replenished as necessary. The piston

serves as the main actuator, converting the linear motion from the brake pedal

into hydraulic pressure. The primary and secondary chambers regulate the

distribution of hydraulic pressure to different brake circuits, ensuring

balanced braking. Seals prevent any leakage and maintain the integrity of the

system.

Classification:

1. Single-Circuit Master Cylinder:

This type of master cylinder has a single chamber and is commonly used in older

vehicles or simpler brake systems. In case of a failure in the brake system,

such as a leak or loss of hydraulic pressure, the entire braking system becomes

compromised. Therefore, this design is considered less safe and is now rarely

used in modern vehicles.

2. Dual-Circuit Master Cylinder:

Dual-circuit master cylinders feature two separate chambers that supply

hydraulic pressure to two independent braking circuits, usually the front and

rear brakes. This design enhances safety by providing redundancy. If one

circuit fails, the other circuit can still operate, ensuring partial braking

capability. Most modern vehicles are equipped with dual-circuit master

cylinders.

3. Tandem Master Cylinder:

Tandem master cylinders are similar to dual-circuit master cylinders but with

an additional safety feature. They consist of two separate pistons, each

operating its own braking circuit. This design increases safety by providing

independent control over the front and rear brakes and ensures proper braking

in case of a failure in one circuit.

(Image-source-network)

Conclusion:

The brake master cylinder is a vital component in the automotive braking

system, responsible for converting mechanical force into hydraulic pressure.

Understanding its working principle and classification helps us appreciate the

importance of this component in ensuring safe and reliable braking. With the

advancements in automotive technology, the dual-circuit and tandem master

cylinders have become standard, providing enhanced safety features and

improving the overall braking performance of modern vehicles.