Brake fluid ingress or air mixing: Water causes rust inside the cylinder, and air causes a decrease in hydraulic transmission efficiency, both of which will lead to weakened or failed braking force.

Component aging and quality problems

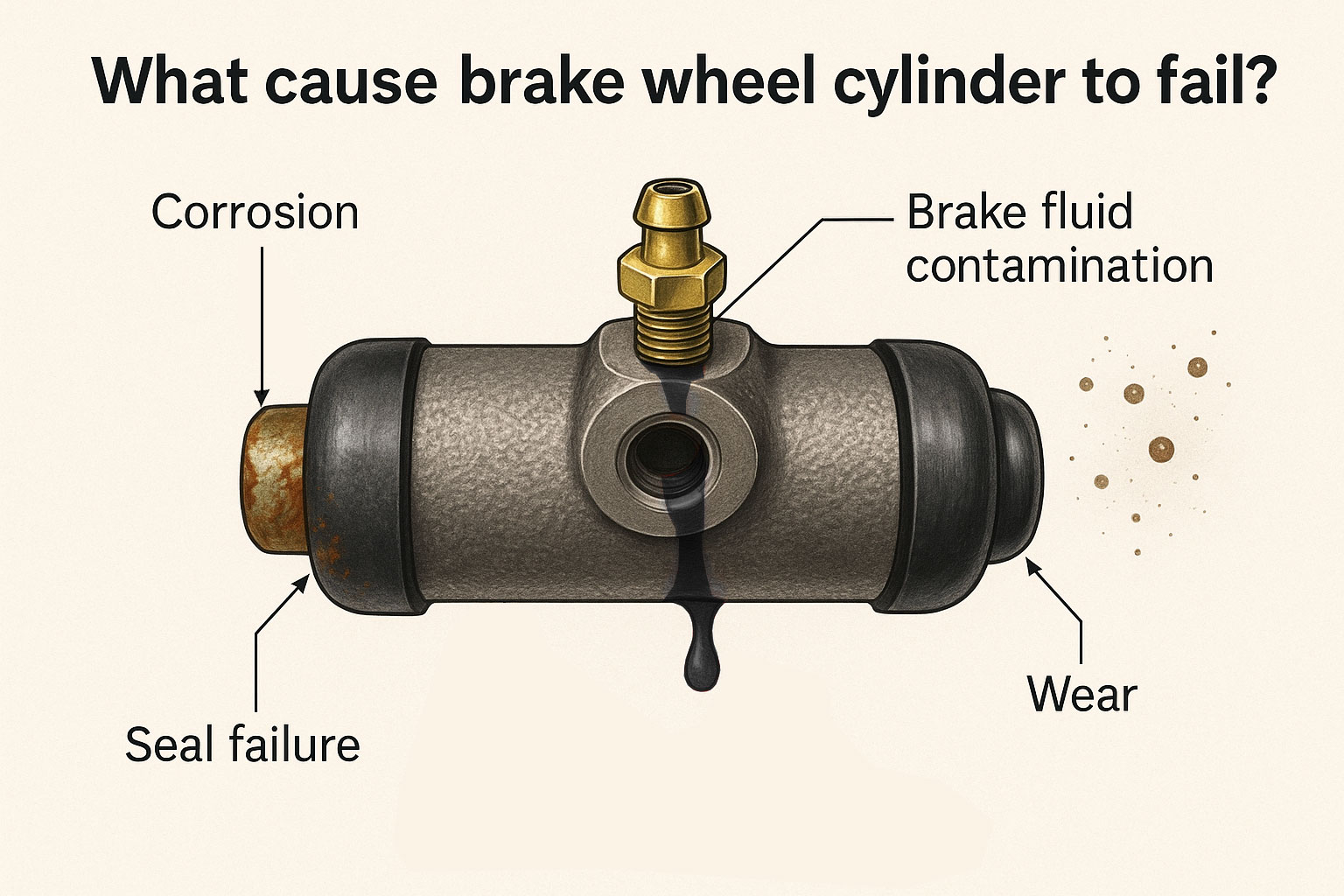

Seal damage: The piston cup of the cylinder is aging, cracked or the seal ring is damaged, resulting in brake fluid leakage and oil pressure cannot be maintained.

Piston stuck or rusted: The long-term failure to replace the brake oil causes the piston of the cylinder to rust and get stuck, unable to return to its position normally, causing dragging or locking.

Quality defects of the slave cylinder: such as poor material or insufficient processing accuracy (such as mismatch between the piston and the cylinder), often occur in low-grade products. Choosing a reliable China supplier brake wheel cylinder can reduce the risk of premature failure.

Improper maintenance

Exceeding the limit of brake pads/discs: Brake pads worn to the limit or deformed brake discs increase the workload of the slave cylinder, and long-term overpressure operation causes damage to it.

Brake fluid is not replaced regularly: Brake fluid that exceeds the replacement cycle (usually 2 years) has strong hygroscopicity and is prone to corrosion and bubbles.

Improper free travel adjustment: The pedal free travel is too small or there is no travel, and continuous pressure on the slave cylinder causes overheating and damage.

Mechanical damage and blockage

Oil pipe rupture or joint leakage: Hydraulic line leakage directly leads to insufficient pressure in the slave cylinder. Compensation hole/vent blockage: The blockage of the compensation hole of the master pump affects the flow of oil, resulting in interruption of oil supply to the slave cylinder.

External pollution and corrosion

Brake dust or muddy water intrusion into the guide pin or piston of the wheel cylinder aggravates wear and corrosion, affecting the flexibility of piston movement.

Electrical failure (partial electronic wheel cylinder)

Abnormal voltage (too high/too low) may cause the motor of the electronic wheel cylinder to burn out or the control module to fail.

Brake wheel cylinder failure is mostly caused by improper oil management (the highest proportion), sealing system collapse, and maintenance deficiency, and a few involve manufacturing defects or external pollution. For vehicle owners looking for durability and affordability, selecting products with factory price brake wheel cylinder options from trusted manufacturers is essential. Regular replacement of brake fluid (every 2 years or 40,000 kilometers), timely inspection of brake pad/disc wear, and avoidance of inferior oil products are the key to prevention.